Solid top hobs

We manufacture customised solid top hobs, using a Lean Manufacturing approach to ensure delivery on time and on budget. Our solid top hobs offer even heat distribution and excellent scratch and knock resistance.

Timely and cost-effective manufacturing of solid top hobs

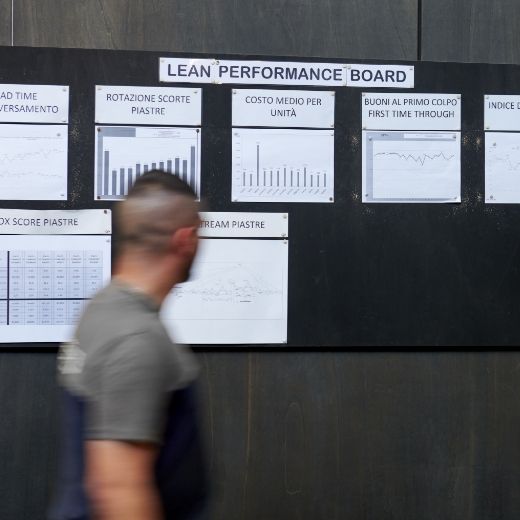

We adopt the Lean Manufacturing principles to minimise waste and constantly improve our manufacturing processes.

Analysis and co-design

Lean and agile manufacturing

Meeting deadlines

Constant technological support

Excellent heat distribution and durability

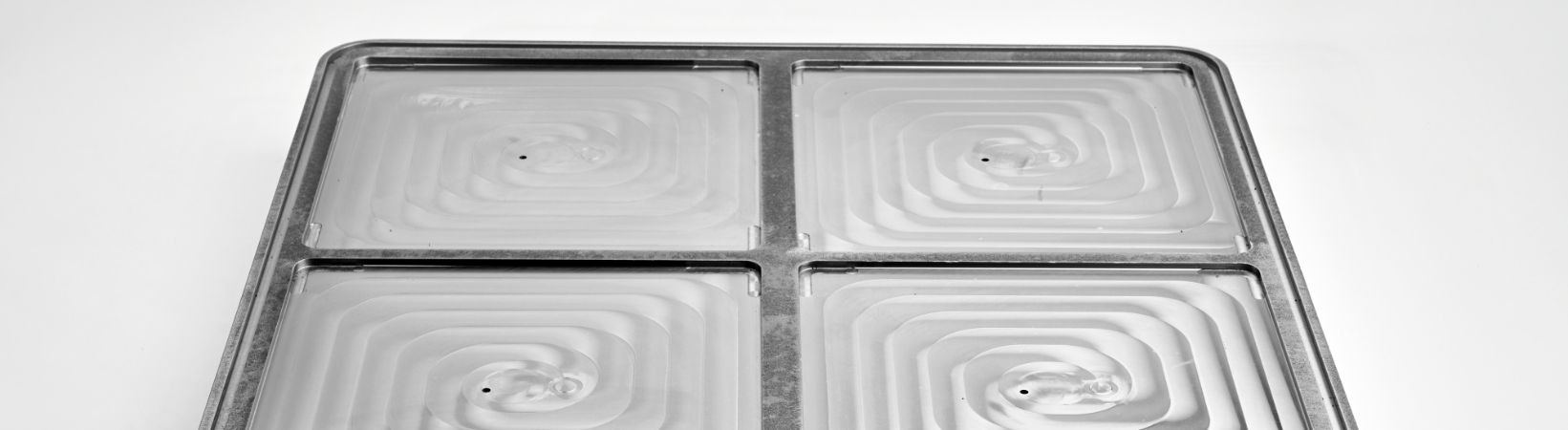

Our solid top hobs are a versatile and efficient solution for heating pots and pans.

Our solid top hobs guarantee even heat distribution over the entire surface, ensuring that every point on the hob is at the set temperature.

Manufactured from high-quality materials, solid top hobs are extremely resistant to scratches and dents caused by pots and pans, ensuring a long service life in professional use.

The surface roughness can be customised to suit individual requirements. They are available for gas, induction and electric cooking.

- Even heat distribution

- Resistance to scratches and dents from pots and pans

- Aesthetic satin finish with different roughness levels

Our solid top hobs for professional catering are designed to ensure the best thermal response, minimising dimensional deformation at high temperatures.

Types of solid top hobs

POLISHED OR SATIN-FINISH CHROME-PLATED S355J2+N STEEL SOLID TOP HOB

Material: S355J2+N

Treatment: chrome plating with 50 μm electrolytically deposited hardchrome

Top: smooth

Surface finish: mirror-polished satin-finish roughness 3.6 Ra

SATIN-FINISH S355J2+N STEEL SOLID TOP HOB

Material: S355J2+N

Top: smooth

Surface finish: satin-finish

SATIN-FINISH CHROME-PLATED 16Mo3 STEEL SOLID TOP HOB

Material: 16Mo3

Treatment: chrome plating with 50 μm electrolytically deposited hardchrome

Finish: smooth

Surface finish: satin-finish roughness 3.6 Ra

SATIN-FINISH 16Mo3 STEEL SOLID TOP HOB

Material: 16Mo3

Top: smooth

Surface finish: satin-finish

SATIN-FINISH CHROME-PLATED 13CrMo4-5 STEEL SOLID TOP HOB

Material: 13CrMo4-5

Treatment: chrome plating with 50 μm electrolytically deposited hardchrome

Top: smooth

Surface finish: satin-finish roughness 3.6 Ra

SATIN-FINISH 13CrMo4-5 STEEL SOLID TOP HOB

Material: 13CrMo4-5

Top: smooth

Surface finish: satin-finish

NICKEL-PLATED 13CrMo4-5 STEEL SOLID TOP HOB

Material: 13CrMo4-5

Treatment: nickel plating with 20 µm

Top: smooth

Surface finish: satin-finish various roughnesses

All steel cooking plates can be assembled using robotic TIG or MIG welding with upstands, splash guards, or other special components.

Why trust Smartech Italia for the manufacturing of solid top hobs

We ensure timely and on-budget delivery through optimised manufacturing, based on the principles of Lean Management.

The manufacture of solid top hobs is entirely build-to-order, allowing performance to be tailored to specific customer requirements.

This approach ensures a customised, high-performance design.

- Short and precise deadlines

- Great quality of materials and manufacturing processes

- Minimum batch size = 1

- Optimised quality and costs

Look at our manufacturing process

Book your call

Indicate the time you prefer to have one of our technicians call you.